Materials for

Use the same polymers, composites, and metals found in familiar manufacturing processes, ーfrom injection molding to machiningー thanks to METHOD’s unique environmental control features.

LOW TEMPERATURE POLYMERS

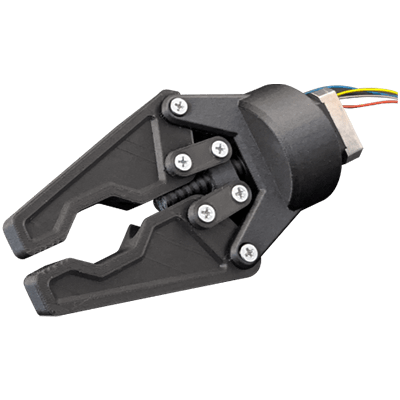

Print complex mechanical assemblies with real production materials.

PLA

Easy to use

52-49°C / 125-120°F

HDT (ASTM 648, 66 psi)

62 MPA / 8,990 PSI

TSY (ASTM D638, 50 mm/min)

TOUGH

Durable and Easy

52-49°C / 125-120°F

HDT (ASTM 648, 66 psi)

35 MPA / 5,080 PSI

TSY (ASTM D638, 50 mm/min)

PETG

Chemical Resistance

70°C / 158°F

HDT (ASTM 648, 66 psi)

44 MPA / 6,380 PSI

TSY (ASTM D638, 50 mm/min)

PETG ESD

Static Resistance

67.4°C / 89.6°F

HDT (ASTM 648, 66 psi)

38.8 / 5,511 PSI

TSY (ASTM D638, 50 mm/min)

NYLON

Abrasion Resistance

91°C / 196°F

HDT (ASTM 648, 66 psi)

66 MPA / 9,570 PSI

TSY (ASTM D638, 50 mm/min)

COMPOSITES

Produce tools and end parts with improved strength, stiffness, and heat-deflection

N6 CARBON FIBER

Peak Strength

184°C / 363.2°F

HDT (ASTM 648, 66 psi)

110 MPA / 15,954.2 PSI

TSY (ASTM D638, 50 mm/min)

N12 CARBON FIBER

Strength + Moisture Resistance

154°C / 309.2°F

HDT (ASTM 648, 66 psi)

66 MPA / 9,572 PSI

TSY (ASTM D638, 50 mm/min)

ABS CARBON FIBER

Strength

N/A

HDT (ASTM 648, 66 psi)

35.7 MPA / 5,177 PSI

ISO 527-2/5A/50

METALS

Print real metal components and tools when nothing else will do